Traditional Sealing Methods

Introduction

Let us start this session with a question. Which pump part contributes to most % of pump failures?

As per the survey by Euro pumps association, 39% of the pump failures are contributed by the shaft seal ( highest among the equipment)

Good Day Everyone,

This is Karthik and Welcome to the Mag Sealless Pump Basics for process industries.

Overview

A brief overview of this lesson.

Firstly, Traditional sealing methods and their limiting factors.

Secondly, Magnetic coupling, Demagnetization ( Cause and effect) Then, the ETFE Lined Pumps

It’s advantages and essential accessories to ensure reliable operation.

Typical Applications of our previous installations, so that you can consider to apply it in a similar application of yours.

Then, a bit about PP/PVDF Mag Drive Pumps

Traditional Sealing Methods

Now the question to you, why the hustle of having a shaft seal. Just have a look at this pump cross-section and let me know. Why don’t we use a static O-Ring to seal a wet end? Just one part would be easy to replace, isn’t it?

But the reality is having a static o-ring as a primary seal will generate a lot of heat. Hence, it will result in deformation/ rubbing marks on the shaft, damages the O-ring, affects the product liquid.

That’s why you need a dynamic sealing method.

Let us look at the traditional sealing methods.

Single Pusher Seal

If you take the single pusher seal, we have a rotor/primary ring, stator /mating ring, a spring, and a secondary seal i.e, elastomers.

Questions – Does a seal leak indicates a seal failure?

The sealing gap between the primary ring and mating ring is required to flush/lubricate the seal faces.

It is adjusted to provide an optimum /minimum leak.

API 682 allows 56.9g/hr of fluid to leak to the atmosphere ( If you refer the seal integrity test . ) for a single seal.

=> 56.9 ml/hr of water . i.e. ,0.0569 kg/hr. Air density = 1.2674kg/m3 . Leak of 0.04457 m3/hr .i.e, 742ml/min of air. )

But for corrosive/hazardous/toxic fluids, every ml counts as there could be strict regulations on emissions.

Hence, considering the regulations and operator’s safety, we might have to put in a double seal (pressurized/unpressurized) and manage the leakage by a seal support system. But a double seal always has high operational and maintenance costs due to their safety instruments and protocols associated with it.

So how do we overcome this scenario then?

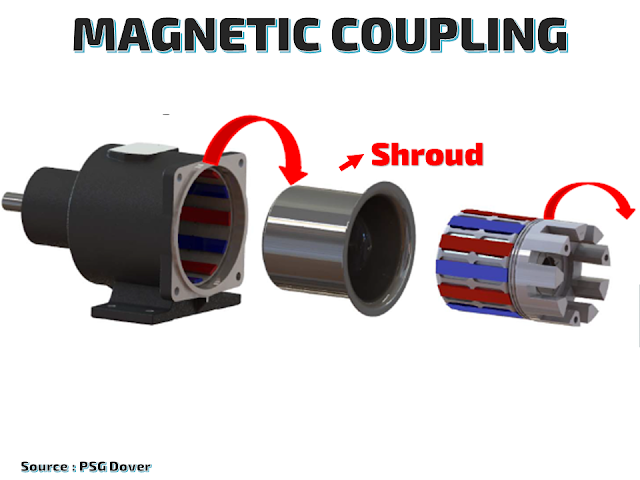

Magnetic Coupling

Well, one of the solutions could be to look at using a

magnetic coupling and separate the contact between the driver and the driven .

( Much similar to Wifi ). i.e, contactless operation.

As you see, there is an outer magnet, inner magnet

separated by a shroud enclosing the inner magnet.

In this way, we eliminate the dynamic sealing method, hence achieve zero leakage.

If you would like to understand more about this segment, here is the youtube video link for the same.

In the next video, we are going to take a look at magnets, its strengths and limitations, stay tuned.

Image

Credits:

- Mechanical Seal - BW Seals,

- Magnetic Coupling - PSG Dover.

- All other photos are licensed under CC by NC 2.0.

Comments

Post a Comment